Gebraucht AMAT / APPLIED MATERIALS eMax CT+ #293727706 zu verkaufen

URL erfolgreich kopiert!

Tippen Sie auf Zoom

ID: 293727706

Wafergröße: 12"

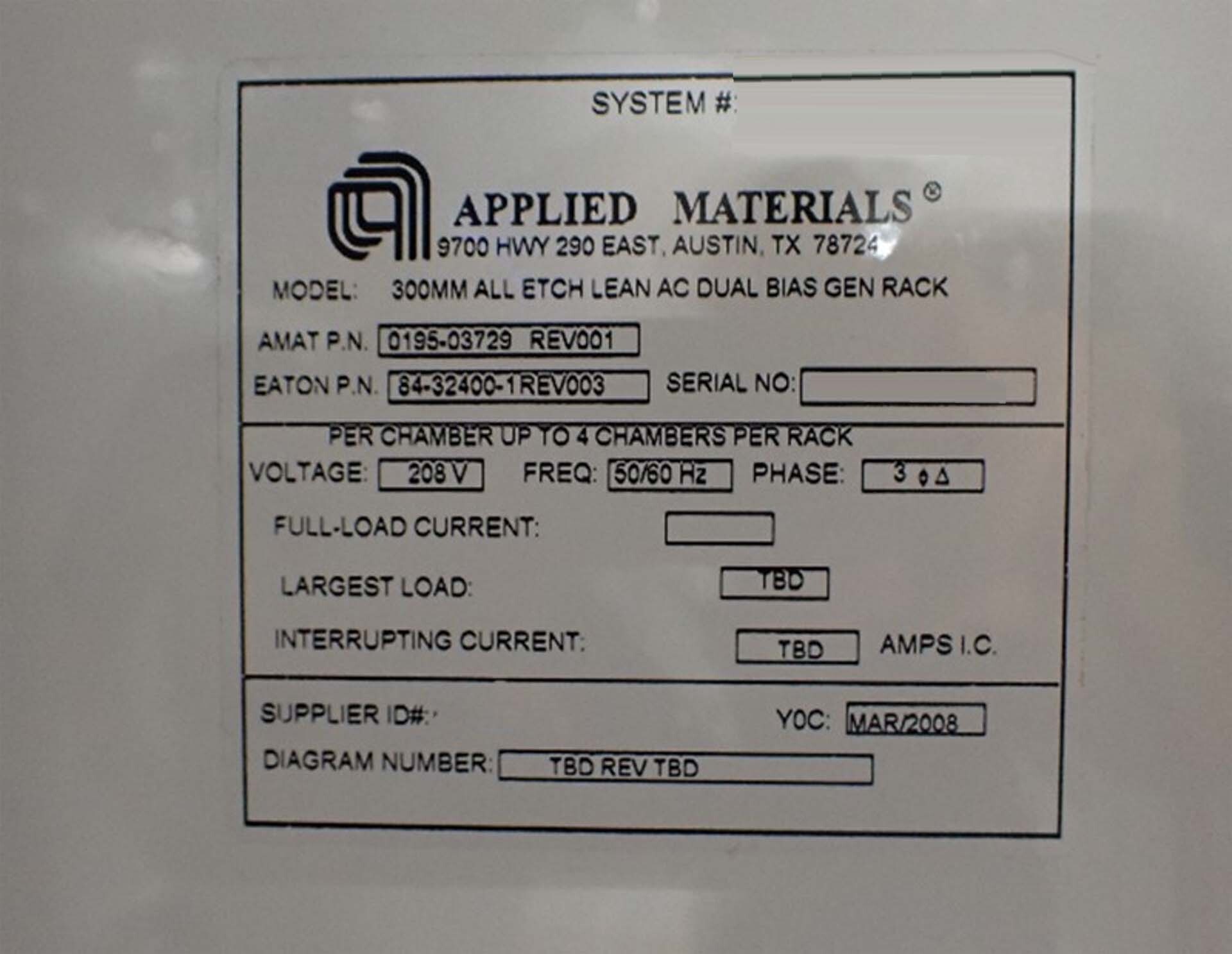

Weinlese: 2008

Etcher, 12"

Wafer cooling method: Wafer backside cooling by He gas

Wafer holding mechanism: Electrostatic adsorption (Ceramic ESC)

Chamber material: 6061-T6 Aluminium alloy

Chamber evacuation: Exhaust with a backing pump

Ultimate pressure: ≤ 1.3 x 10^-3 Pa

Chamber leak amount: ≤ 266 mPa/min

Pressure monitor: 1333 Pa

Pressure measurement range: 0 to atmospheric pressure

Pressure control: Throttle valve

Pressure interlock: half atom switch

Wall / Cathode temperature control: heat exchanger

Chamber wall circulating water flow sensor

Chamber cathode circulating water flow sensor

Process Kit: RAISED Si / Si

KALREZ 8575 Dry Clean Chamber vacuum seal

EDWARDS STP-A1603P 1600L/S 2 Turbo Pump

TOYOTA T100L Pump

EBARA ESR80WN Pump

MKS/ENI GHW12 RF Generator, 13.56 MHz, 1250 W

MKS/ENI B-5002-0SPECTRUM RF Generator, 2 MHz, 5000 W

ADVANCED ENERGY VHF2760 RF Generator, 60 MHz, 2700 W

Endpoint specification: Eye-D / 200-800nm

HV Power supply

Chamber liner: Yttrium liner

Gas panel specification:

AERA PI-980 MFC

Gas line connection: Single Line Drop (SLD) connection

SLD Specification:

TESCOM SLD Regulator

ENTEGRIS SLD Filter

CKD SLD Manual valve

Gas / Size

C4F6 / 100 SCCM

CH2F2 / 100 SCCM

CH3F / 100 SCCM

C4F8 / 100 SCCM

CF4 / 300 SCCM

CHF3 / 300 SCCM

O2 / 2000 SCCM

O2 / 200 SCCM

O2 / 20 SCCM

Ar / 200 SCCM

Ar / 2000 SCCM

N2 / 200 SCCM

(2) Load lock chambers:

Slow pump / fast pump switchable

Equipped with cool down function

Chamber material: 6061-T6 Aluminum alloy

Chamber pressure monitor: Convectron gauge

Chamber vacuum sealing method: Viton O-Ring

VAT Slit valve

Ultimate pressure: ≤ 13.3 Pa (100mTorr)

Chamber leak amount: ≤ 1.33 Pa (10mTorr/min)

Transfer chamber:

Chamber pressure control: Auto Pressure Control (APC)

Chamber material: 6061-T6 Aluminum alloy

Chamber pressure monitor: Convectron gauge

Chamber vacuum sealing method: Viton O-Ring

VAT Slit valve

Wafer transfer robot

Wafer blade: Dual blade

Chamber evacuation

Ultimate pressure: ≤ 13.3 Pa

Chamber leak amount: ≤ 1.33 Pa

Remote signal tower

Factory interface:

YASKAWA LM Track Atmospheric Transfer robot

No Right and left side storage pod

(3) Loadports

25-Wafers FOUP

No ionizer

E84 PIO Sensor

E99 Carrier ID

Wafer mapper

Power supply: 200/208 V, 60 Hz

2008 vintage.

Es liegen noch keine Bewertungen vor